Hit enter to search or ESC to close

Double Layer Ceiling Solution

Jump to

Double Layer Ceiling Solution

Our two-layer solution includes a dense first layer, ensuring the expected thermal performance is still delivered when compressed. Learn more below.

The problem

We are seeing greater use of a two-layer system, often with traditional R3.6. However, this reduces thermal performance as the:

- weight of the second layer compresses the first layer

- thickness of the first layer sitting above the adjacent truss chords creates a channel for air flow.

The solution

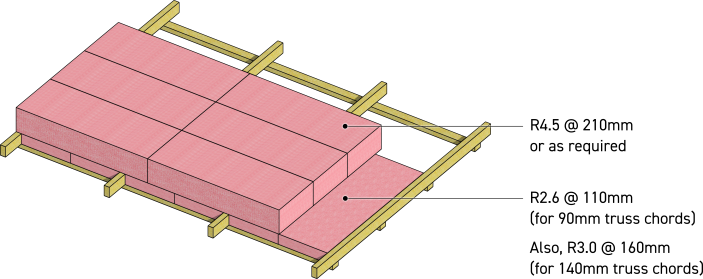

The Comfortech® two-layer solution uses a:

- first layer of high-density Pink® Superbatts® insulation that is the combined height of the truss chord and the gap to the top of the ceiling batten. This layer would be either 110mm for a 90mm truss chord, or 160mm for a 140mm truss chord.

- second layer of over-width (460mm wide) Pink® Superbatts® insulation, installed at right angles to the first layer.

When the two layers are installed, the thermal bridge is completely closed, and the insulation performs as modelled.

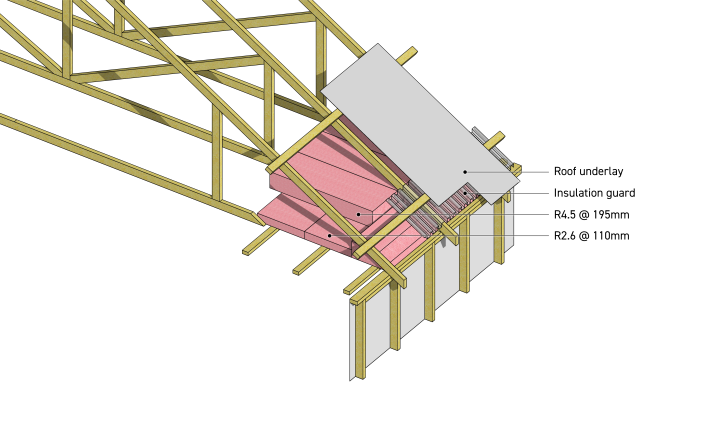

Insulation Guard

As roof insulation increases in thickness to meet the new code, there is a greater differential in the surface temperature of the ceiling versus that of the top of the insulation. Therefore, warm air that escapes the warm interior through leakage and enters the roof cavity will likely condense; creating condensation; hence ensuring the adequate ventilation of the roof cavity is becoming mor critical under the new code. Under the new H1, the last 500mm of the perimeter of the roof insulation can be reduced to R3.3; this allows the insulation to carried out over the top plates of the wall, while reducing the barrier to air flow from the eave edges. There is however still a high risk, particularly in roofs with a pitch below 30 degrees of the insulation touching the underside of the roof underlay, preventing ventilation of the roof space and creating a condensation and mould risk. Therefore, we recommend the installation of a roll panel vent over the trusses, under the underlay, to maintain this critical ventilation pathway.

With an insulation guard specified and installed at the roof edge, edge compression of the Pink® Superbatts® ceiling insulation can then be utilised to avoid the need for a raised heel. This can offer a significant cost saving and avoid ‘height in relation to boundary’ issues, as well as simplifying the installation process. For more information how edge compression can be utilized with Pink® Superbatts®, please visit our Edge Compression Calculator.